Dana-Seals A/S

Quality & Compliance

The quality assurance at Dana-Seals is based on a range of stringent steps. We ensure that our seals always comply to the highest and most environmentally careful standards

Quality: Danish R&D, production, and test lab

To maintain our position as one of the market’s highest quality providers, we use our more than 45 years of experience to run our R&D, production and test lab in Elsinore, Denmark.

Quality assurance and traceability

Quality assurance is part of every step in the process flow, and data is documented at every step. Each Dana product is verified for correct process- and product quality – all the way from raw material to final product.

- Purchasing

- Compound production

- Isostatic moulding

- Sintering

- CNC machining

- Finishing processes

- Helical spring production

- Packing

- Continuous quality control

Documentation

- MDS

- ISIR

- COC

- PPAP

- FMEA

- Control plan

- Process flow

For any other needs for documentation, please contact our technical department

Dana-Seals A/S

Policies and certifications

The quality assurance at Dana-Seals is based on a range of stringent steps. We ensure that our production, processes, and products always comply to the highest and most environmentally careful standards

ISO certifications

ISO 9001

The Quality Management Standard ISO 9001 certification ensures full traceability on all processes and procedures that control our production and the services we provide.

ISO certifications

ISO 14001

ISO 14001Environmental focused business is described and controlled through ISO 14001 certification

we are environmentally certified with the Environmental Management System ISO 14001.

EU and DK Regulations

Compliance to Danish and European regulations

The Danish Working Environment Authority checks compliance with the Danish health and safety rules. Conditions checked are Dana-Seals A/S’ health and safety performance and ergonomics, noise and the risk of accidents.

Elite inspection report from the Danish Working Environment Authority can be found here.

Dana-Seals A/S manufactures specific materials which are compatible with food contact and meet all requirements of European Regulation EU 1935/2004 and EU regulation No. 10/2011/EC.

Elite inspection reports from the Danish Veterinary and Food Administration can be found here.

The Danish Working Environment Authority checks compliance with the Danish health and safety rules. Conditions checked are Dana-Seals A/S’ health and safety performance and ergonomics, noise and the risk of accidents.

Elite inspection report from the Danish Working Environment Authority can be found here.

Dana-Seals A/S manufactures specific materials which are compatible with food contact and meet all requirements of European Regulation EU 1935/2004 and EU regulation No. 10/2011/EC.

Elite inspection reports from the Danish Veterinary and Food Administration can be found here.

EU and DK Regulations

Compliance to Danish and European regulations

The Danish Working Environment Authority checks compliance with the Danish health and safety rules. Conditions checked are Dana-Seals A/S’ health and safety performance and ergonomics, noise and the risk of accidents.

Elite inspection report from the Danish Working Environment Authority can be found here.

Dana-Seals A/S manufactures specific materials which are compatible with food contact and meet all requirements of European Regulation EU 1935/2004 and EU regulation No. 10/2011/EC.

Elite inspection reports from the Danish Veterinary and Food Administration can be found here.

All our PTFE products, comply with the two European Union directives: REACH and RoHS

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

REACH applies to all chemical substances; not only those used in industrial processes, but also in our day-to-day lives, for example in cleaning products, paints as well as in articles, such as clothes, furniture, and electrical appliances. Therefore, the regulation has an impact on most companies across the EU.

The RoHS (‘Restriction of Hazardous Substances’) bans a range of substances that are present in electrical equipment, e.g., lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB), polybrominated diphenyl ether (PBDE), bis(2-ethylhexyl) phthalate (DEHP), butyl benzyl phthalate (BBP), dibutyl phthalate (DBP), and diisobutyl phthalate (DIBP).

PFAS

We can confirm that there are no PFAS emissions in connection with the production of the PTFE we use. Nor is it in the finished products.

Statement of compliance

Responsible management at Dana-Seals A/S

Compliance to social and environmental issues

In an ever-evolving high-tech world, many products are discarded and end up in landfills. Dana-Seals wants to do our part to protect human health and the environment from the risks posed by chemicals. We strive to use the most eco-friendly suppliers and sustainable products and procedures available.

Responsible management at Dana-Seals A/S

Compliance to social and environmental issues

Today, responsible management entails achieving tangible results while continually initiating processes that can benefit our planet. For Dana-Seals, this presents a complex challenge as PTFE, the core material of our products, not only serves as the market’s most durable and effective material for creating tight sealing solutions but also carries an environmental footprint. Until a new material with similar properties but a reduced environmental impact becomes available, we will continuously implement measures that support our responsible management strategy.

Our mission is to lead in ensuring the proper handling of PTFE, advocating for environmental responsibility, and driving change within our industry. Our dedication extends beyond the present, as we actively seek innovative solutions to shape a future that is more environmentally responsible and sustainable for generations to come.

- Supporting the circular economy by ensuring that all our waste materials are properly disposed of via a range of approved recycling systems

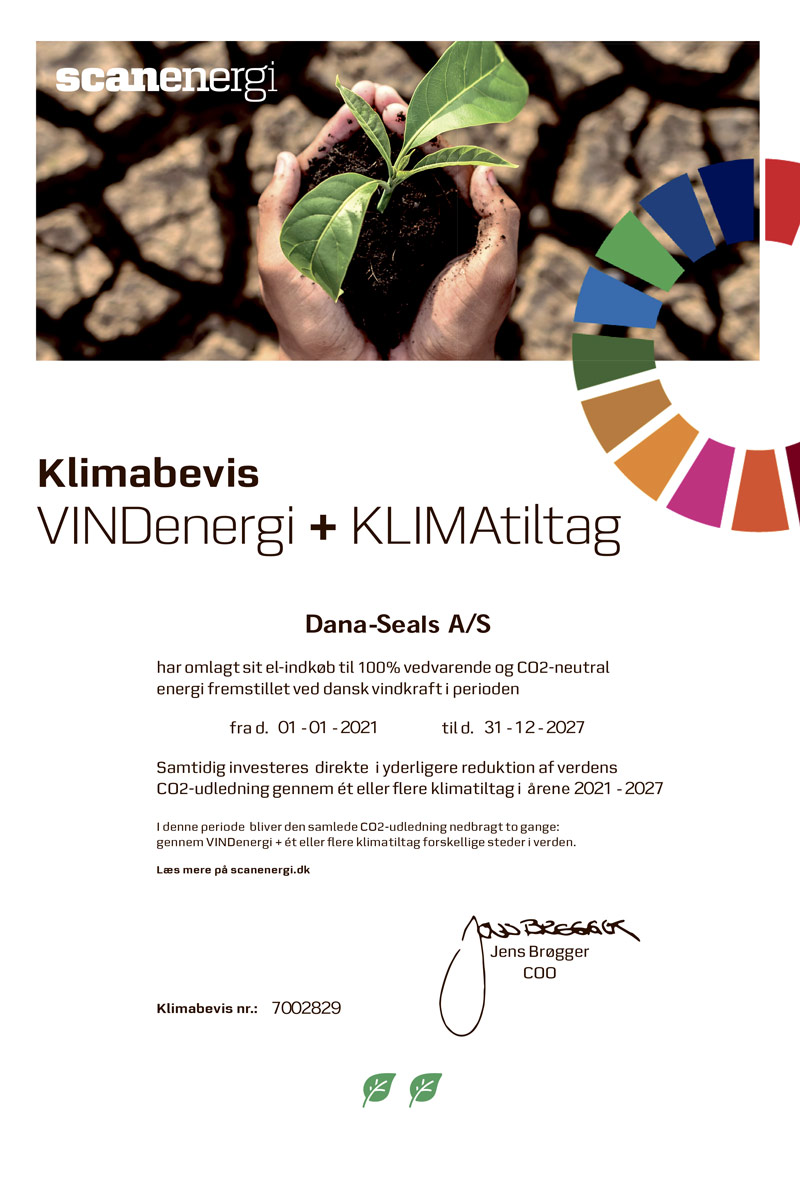

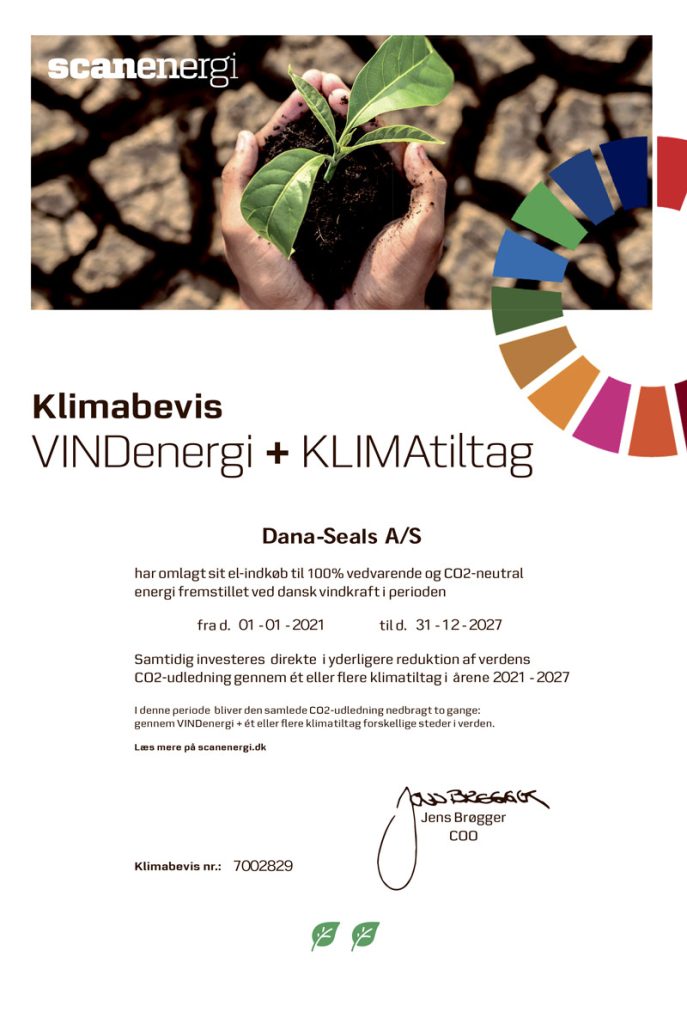

- Converted 100% of our electricity purchase to renewable and CO2 neutral energy produced by Danish wind power and through climate actions in different parts of the world

- Developing seal designs with very low friction, which conserves resources

- Annual Climate Report: Since 2020, we have made internal annual climate reports to track our environmental impact and identify areas for improvement.

- Responsible Product Handling and Disposal: We ensure that our waste materials are properly disposed of via a range of approved recycling systems. We also inform our partners to handle our products and packaging responsibly and in accordance with the law when disposing of them after use.

- Reducing consumption: To conserve resources, we develop seal designs with the lowest possible friction, employ methods to reduce material consumption, and work towards eliminating harsh chemicals from our daily production.

- CO2 neutral electricity: Since 2016, we have converted 100% of our electricity purchase to renewable and CO2 neutral energy produced by Danish wind power. We also invest in climate actions through our energy supplier.

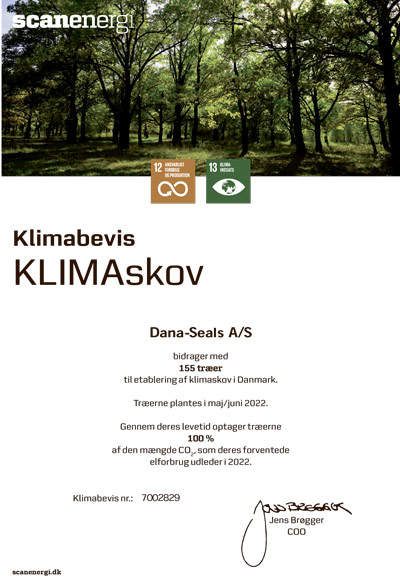

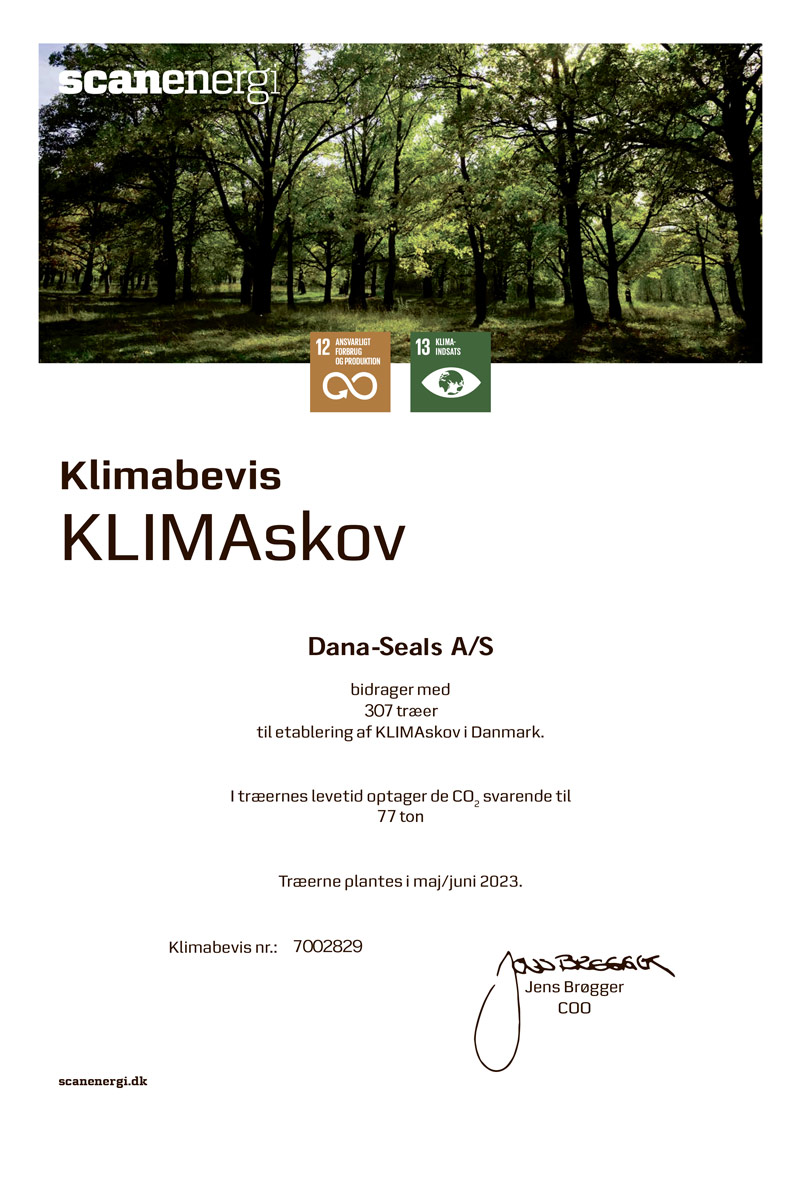

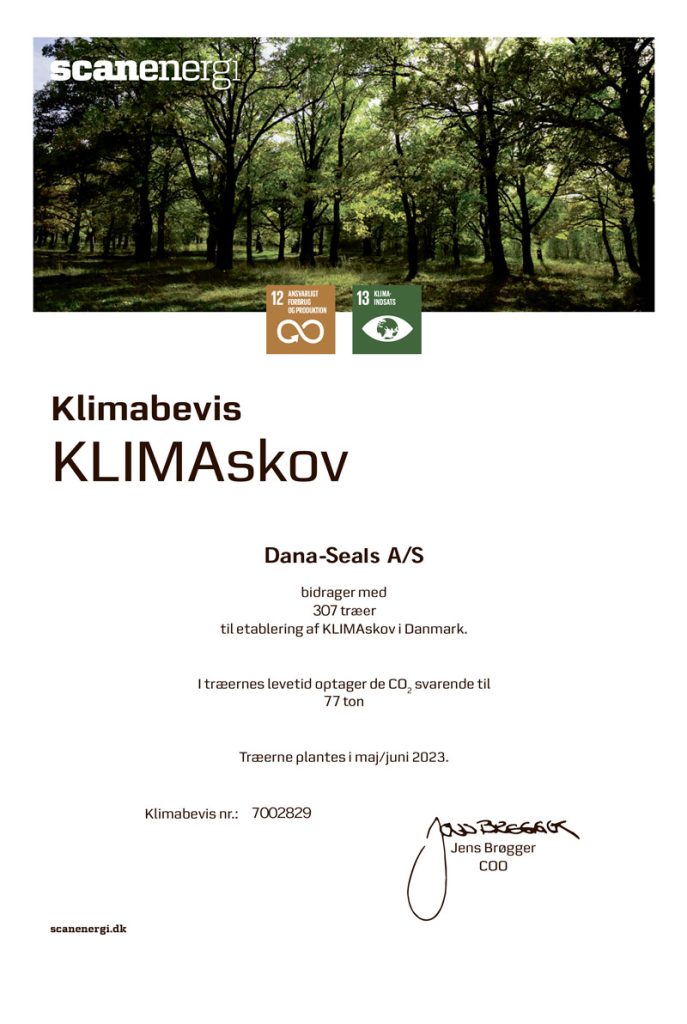

- Planting forest: Since 2022, we have been planting forests in Denmark to capture CO2 and ensure biodiversity. See documentation and certificates below.

- Planting forest: Since 2022, we have been planting forests in Denmark to capture CO2 and ensure biodiversity. See documentation and certificates below.

- Supplier Requirements: We demand that our suppliers comply with REACH and aim to prioritize suppliers that are ISO14001 and ISO9001 certified.

- Only using suppliers that comply with REACH

- Striving to use suppliers that are ISO 14001 and ISO 9001 certified

- Employing methods to reduce material consumption

- Eliminating harsh chemicals from our daily production

- Working with UN World Goal 12 and Goal 13 to ensure responsible consumption and production, and climate action

We demand that our suppliers comply with REACH and aim to prioritize suppliers that are ISO14001 and ISO9001 certified.

We actively collaborate with industry peers to share knowledge and promote responsible handling practices.

We welcome collaborations with universities and non-governmental organizations to develop more sustainable solutions for waste recirculation and development of new environmentally friendly and robust materials.

We are committed to promoting gender equality and aspire to achieve a balanced representation of male and female employees across all facets of our organization, including production, management, and the board. In 2023, our overall representation stands at 44% female and 56% male employees.

Our commitment to work with UN World Goal 12 and Goal 13 ensures that everyone at Dana-Seals actively engage with the sustainable agenda. Through this engagement, we seek knowledge and inspiration to set tangible goals and initiate initiatives, aligning our actions with the global drive for a more sustainable future.

- Cross-Industry Collaboration: We enWe actively collaborate with industry peers to share knowledge and promote responsible handling practices.

- Academic and NGO Partnerships: We welcome collaborations with universities and non-governmental organizations to develop more sustainable solutions for waste recirculation and development of new environmentally friendly and robust materials.

- Diversity and inclusion: We are committed to promoting gender equality and aspire to achieve a balanced representation of male and female employees across all facets of our organization, including production, management, and the board. In 2023, our overall representation stands at 44% female and 56% male employees.

- Honesty and transparency: Our commitment to work with UN World Goal 12 and Goal 13 ensures that everyone at Dana-Seals actively engage with the sustainable agenda. Through this engagement, we seek knowledge and inspiration to set tangible goals and initiate initiatives, aligning our actions with the global drive for a more sustainable future.

Here's how we do it:

- Annual Climate Report: Since 2020, we have made internal annual climate reports to track our environmental impact and identify areas for improvement.

- Responsible Product Handling and Disposal: We ensure that our waste materials are properly disposed of via a range of approved recycling systems. We also inform our partners to handle our products and packaging responsibly and in accordance with the law when disposing of them after use.

- Reducing consumption: To conserve resources, we develop seal designs with the lowest possible friction, employ methods to reduce material consumption, and work towards eliminating harsh chemicals from our daily production.

- CO2 neutral electricity: Since 2016, we have converted 100% of our electricity purchase to renewable and CO2 neutral energy produced by Danish wind power. We also invest in climate actions through our energy supplier.

- Planting forest: Since 2022, we have been planting forests in Denmark to capture CO2 and ensure biodiversity. See documentation and certificates below.

- Supplier Requirements: We demand that our suppliers comply with REACH and aim to prioritize suppliers that are ISO14001 and ISO9001 certified.

- Cross-Industry Collaboration: We actively collaborate with industry peers to share knowledge and promote responsible handling practices.

- Academic and NGO Partnerships: We welcome collaborations with universities and non-governmental organizations to develop more sustainable solutions for waste recirculation and development of new environmentally friendly and robust materials.

- Diversity and inclusion: We are committed to promoting gender equality and aspire to achieve a balanced representation of male and female employees across all facets of our organization, including production, management, and the board. In 2023, our overall representation stands at 44% female and 56% male employees.

- Honesty and transparency: Our commitment to work with UN World Goal 12 and Goal 13 ensures that everyone at Dana-Seals actively engage with the sustainable agenda. Through this engagement, we seek knowledge and inspiration to set tangible goals and initiate initiatives, aligning our actions with the global drive for a more sustainable future.

Let us help you find the right solution

Office, production and test lab

- Dana-Seals A/S

- Ole Rømers Vej 4G

- DK-3000 Helsingør

- Denmark

- info@dana-seals.dk

- +45 4922 4400

-

CVR: 26 16 54 58

Please feel free to contact us with any queries you might have

Monday to Thursday: 8am – 4pm GMT+1

Friday: 8am – 3pm GMT+1